Menu

Menu

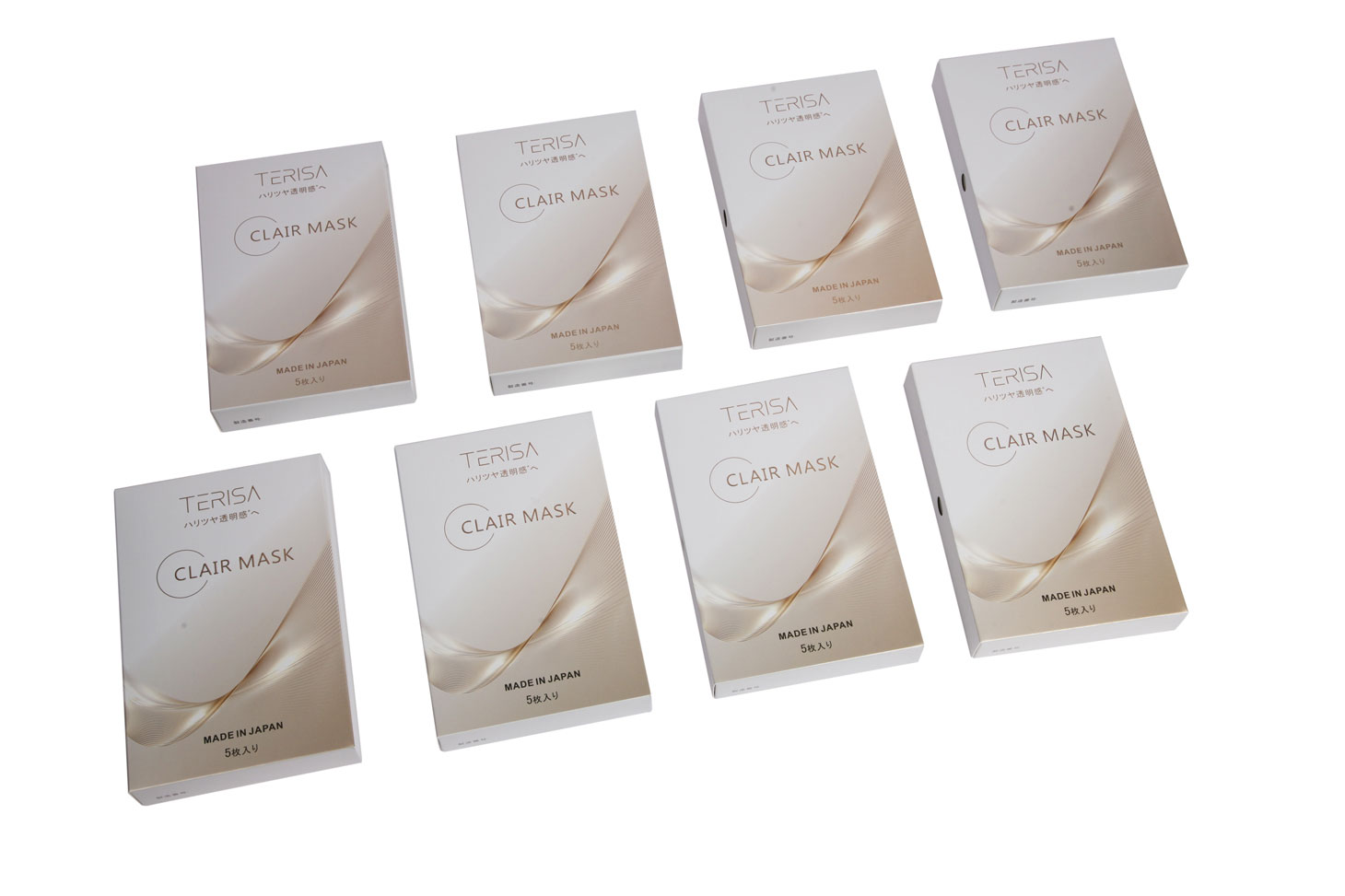

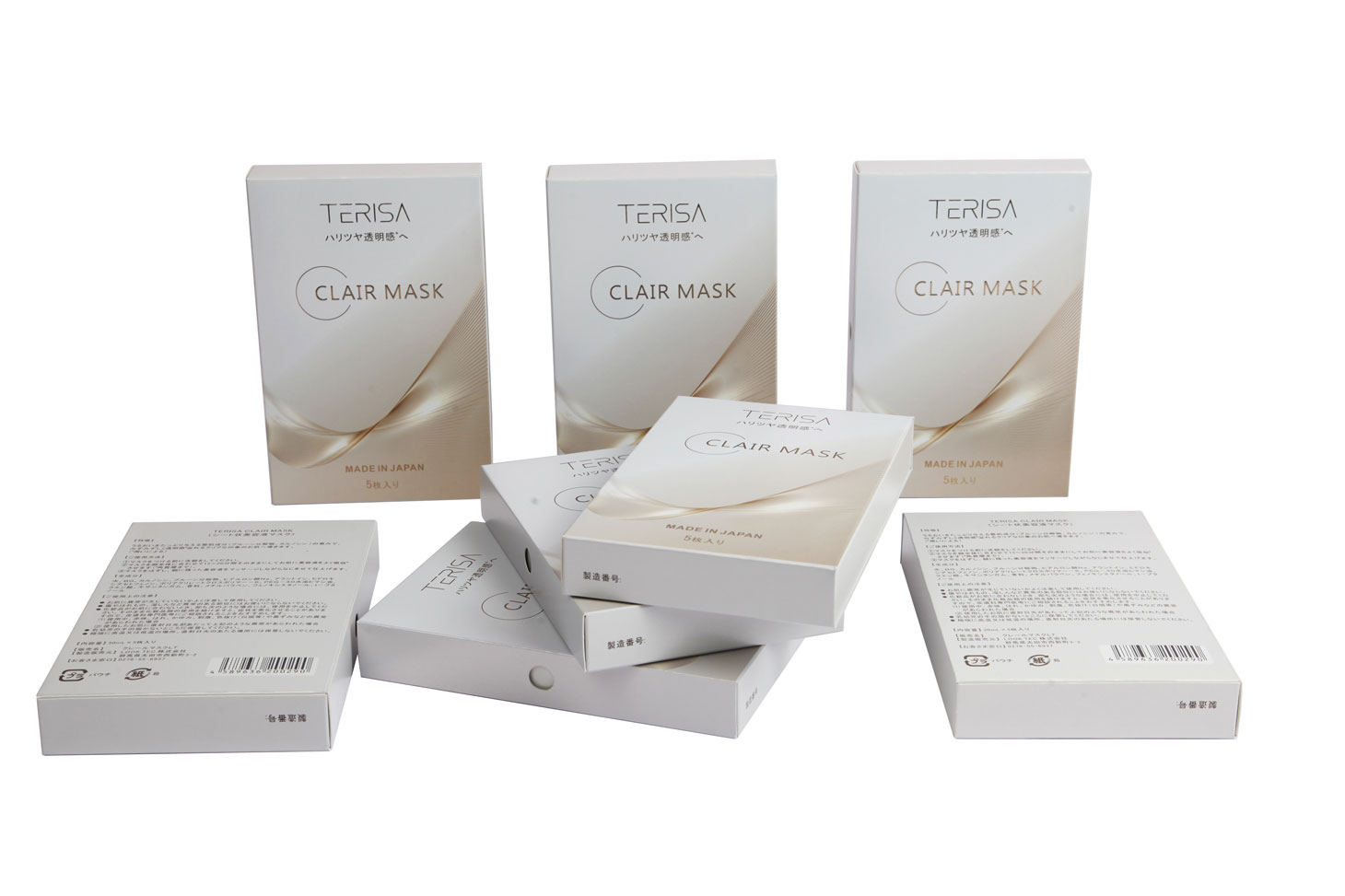

Facial mask packaging box printing is an important part of facial mask products. It not only needs to attract consumers' attention, but also needs to convey the product quality and brand image. This article will introduce the process used in the printing of facial mask packaging box in detail, including design, color selection, printing technology and post processing, to reveal the secret of creating a beautiful appearance and unique brand image for you.

The printing process of facial mask packaging box can be divided into the following aspects: design, color selection, printing technology and post processing.

First, design is the basis of facial mask packaging box printing. Good design can attract consumers' attention and convey the characteristics and brand image of the product. The design of facial mask packaging box needs to consider the function, characteristics and target audience of the product. Designers will create the structural design of the box based on these elements, as well as the arrangement of the appearance pattern, color, and copy of the packaging box. The goal of the design phase is to create a unique and recognizable packaging box design to attract consumers' attention and match the brand image.

Secondly, color selection is a crucial link in the printing of facial mask packaging box. Color can convey the characteristics and brand image of a product, while also influencing consumers' emotions and purchasing desires. In the printing of facial mask packaging boxes, the commonly used colors are bright, soft, warm, etc. The choice of color needs to consider the product's attributes and brand positioning, and be coordinated with the design style to create a unique visual effect.

Next is the choice of printing technology. The printing technology of facial mask packaging box usually includes offset printing, screen printing and bronzing. Offset printing is the most commonly used printing technique, suitable for printing large areas of colors and patterns. Screen printing can be used to print patterns with rich details and many color transitions. Hot stamping is the process of printing metallic patterns on packaging boxes through hot pressing metal foil, giving them a visual sense of luxury. When choosing printing technology, it is necessary to comprehensively consider the design requirements and budget to achieve the best printing effect.

Finally, there is the post processing stage. Post processing can improve the texture and practicability of the facial mask packaging box. Common post processing techniques include lamination, UV polishing, embossing printing, and sanding. Mulching can protect the packaging box from scratches and moisture erosion, while increasing the glossiness of the packaging box. UV glazing can increase the smoothness and tactile feel of the packaging box. Concave printing can create 3D patterns on packaging boxes, increasing the sense of tactile layering. The frosting treatment can create a frosted texture on the surface of the packaging box, increasing its advanced and textured feel.

The process flow of facial mask packaging box printing covers design, color selection, printing technology and post processing. Through careful design and production, you can create a beautiful appearance and unique brand image for facial mask products. When selecting a printing supplier, it is necessary to consider their experience, technical strength, and advanced level of equipment to ensure that the printing effect meets expectations. Meanwhile, timely communication and cooperation are also important factors in ensuring the quality of printed materials.

Manufacturer of packaging products Customized factory for holiday gift boxes Packaging gift box manufacturer Gift box packaging manufacturer Gift Box Customization Customized outer packaging box, customized processing and manufacturing factory Packaging manufacturer

Packaging box design Free packaging design Shenzhen Packaging Design Company